1. What is lightweight concrete?

- Lightweight concrete is a type of concrete processed through production technology such as high pressure distillation or mixed with special materials such as fiber reinforcement, EPS foam beads, aluminum powder, etc. While conventional concrete has a mass of up to 2500kg/m3, lightweight concrete only has a mass ranging from 1200-1900kg/m3

2. How many types of lightweight concrete are there?

- When it comes to direct poured ready-mixed concrete, many people may know, but when it comes to lightweight concrete, many people will still wonder what kind of concrete it is. And many people also do not know that there are many types of lightweight concrete such as autoclaved lightweight concrete, EPS lightweight concrete, Cemboard lightweight concrete, foamed lightweight concrete, etc.

2.1. Autoclaved lightweight concrete:

- Autoclaved aerated concrete is one of the most premium concrete types today. This is a concrete cement mixture made from cement, yellow sand, gypsum, lime, aluminum powder and water. In production, people can also use fly ash from thermal power slag for recycling. The ingredients react with each other to form a foamed concrete mixture with small pores. The pores help increase the volume of the concrete up to 5 times compared to conventional concrete. Then this concrete mixture is put into a steam boiler under high pressure saturated steam. This process continues to help the mixture react with each other. The final product has a porous crystal structure with strong bonds and high pressure resistance.

- In Vietnam, there are two main types of autoclaved aerated lightweight concrete: AAC lightweight concrete bricks and ALC lightweight concrete panels.

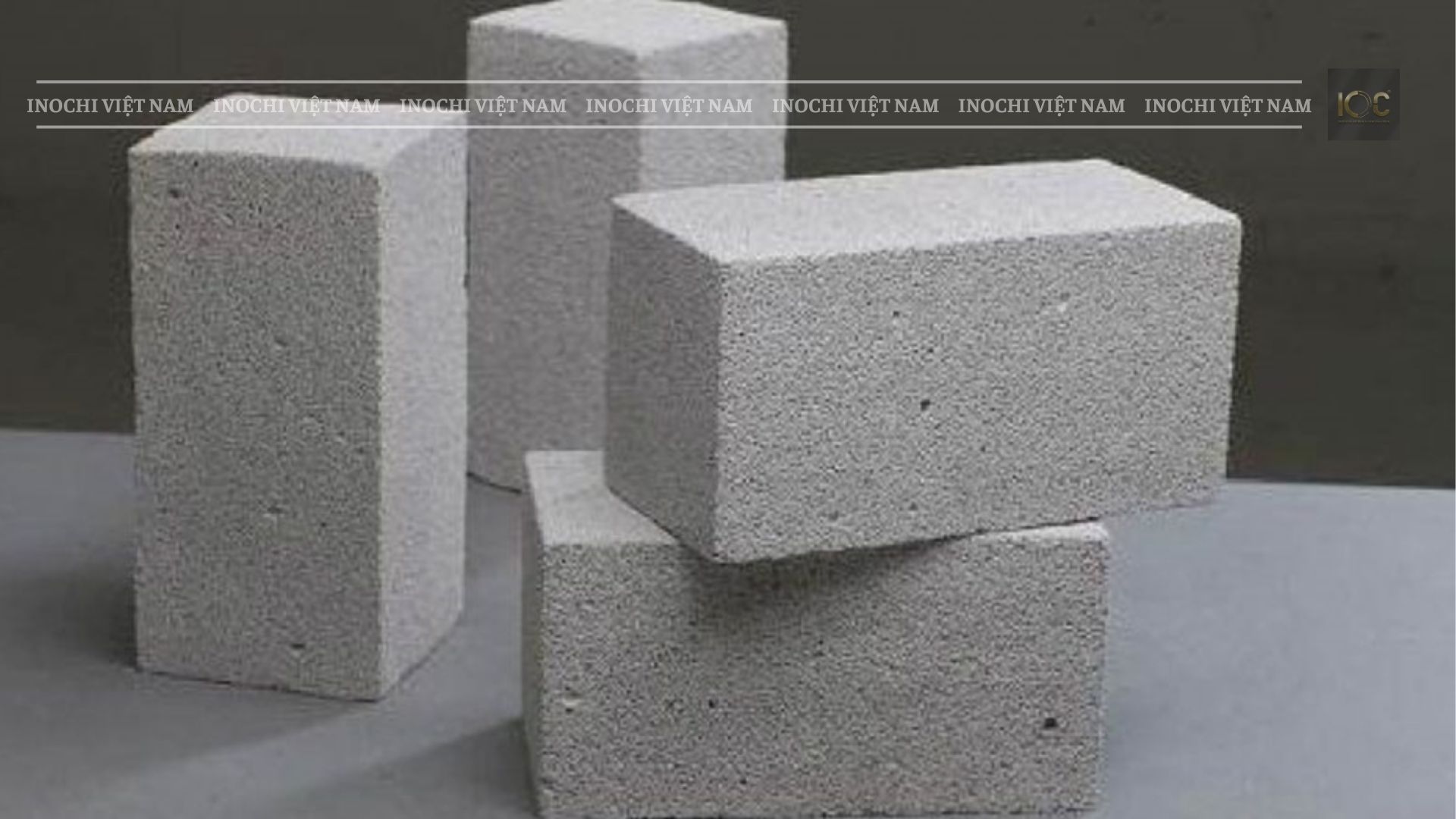

2.1.1. AAC lightweight concrete bricks:

- AAC lightweight concrete bricks are also known as autoclaved aerated concrete bricks or AAC bricks, super lightweight bricks. This type of brick is used to build exterior structures or interior partition walls. The big advantage of this type of brick is that it is 8 times more insulating than regular bricks. After testing, it was found that the highest fire resistance standard index currently reaches EL240, which is 2 times higher than other refractory bricks.

AAC lightweight concrete bricks

- Super light bricks are much larger in size than other types of red bricks and traditional bricks. The standard sizes commonly used are 600x200x100mm, 600x200x150mm, 600x200x200mm corresponding to wall thicknesses of 100, 150, 200mm. In particular, this type of brick has high advantages in heat resistance, sound insulation, insulation and fire resistance. Used to build houses, high-rise buildings, etc.

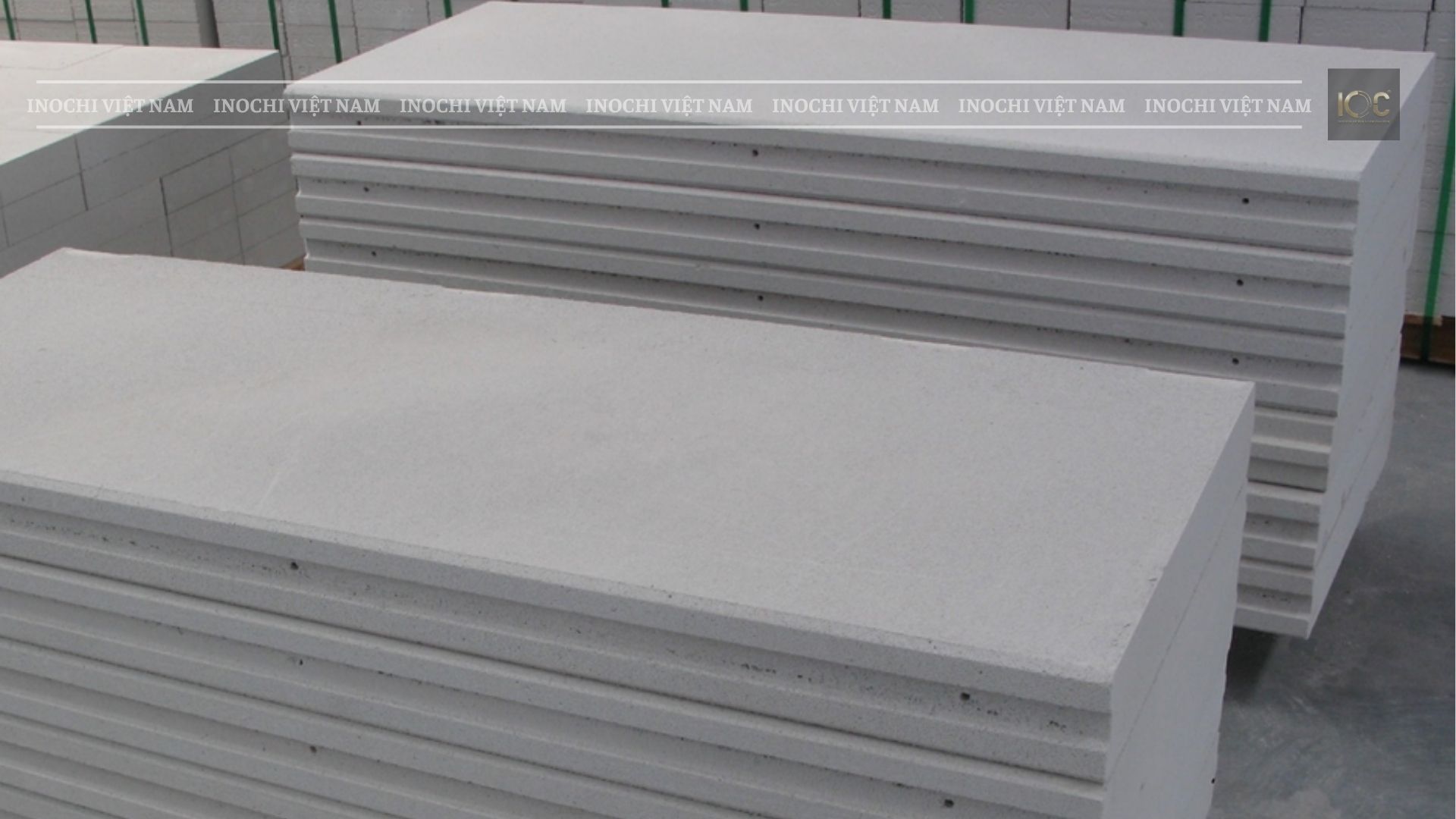

2.1.2. ALC lightweight concrete panels:

- ALC lightweight concrete panels are products that inherit all the outstanding features of AAC aerated concrete such as sound insulation, heat insulation, fire resistance, super light weight, only about 1/3 compared to conventional raw construction materials, and outstanding waterproofing and heat resistance. To best use ALC lightweight concrete panels, it is recommended to combine them with reinforced steel mesh. The 02-layer reinforced steel mesh and the anti-corrosion steel protection layer create a durable reinforced lightweight concrete structure. Thanks to the advent of this type of concrete, construction work has become much more convenient and optimal. This will be the optimal solution for projects such as prefabricated houses, prefabricated houses, industrial buildings, etc. Autoclaved aerated concrete panels are rectangular panels with lengths ranging from 1.2m to 4.8m. The width is 0.6m, the thickness of the concrete panels includes dimensions such as: 7.5cm, 10cm, 15cm and 20cm.

ALC lightweight concrete panels have soundproofing, heat insulation, fire resistance, and super light weight, only about 1/3 compared to raw construction materials.

2.2. EPS lightweight concrete:

- EPS lightweight concrete panels are also known as foam concrete panels or precast concrete panels. This new material, when introduced to Vietnam, has become the main construction material for many projects today. Foam concrete includes: Cement, sand, water, EPS - Expanded Polystyrene and some other additives, ... This type of concrete is produced according to a high-tech process. It has become a material that can replace traditional materials. At the same time, it contributes to environmental protection, especially reducing the global greenhouse effect.

EPS lightweight concrete

2.3. Lightweight concrete Cemboard:

- Cemboard is a lightweight cement in the form of a hard board. Cemboard has a standard size of 1220 x 2440 with different thicknesses, assembled on a pre-formed box iron frame system, positioned with specialized screws, so the construction process is very convenient and fast. The mixture is mixed from natural materials such as portland cement + superfine sand + Limestone + cellulose fibers. They are mixed together, then rolled evenly to a certain thickness, at this time the cellulose fibers will help the materials to be more tightly bonded. Finally, the board is pressed to a certain high strength, trimmed according to standards and then put into an oven at a temperature of 1300oC for 48 hours. This will help the concrete board to be more durable, not warped or deformed during use. Cemboard panels are manufactured on modern French production lines, meeting high standards of flexibility, compressive strength, water resistance, fire resistance, meeting the needs of use in Vietnam and for export.

Cembroad lightweight concrete panels

2.4. Lightweight foam concrete:

- Aerated lightweight concrete is lightweight concrete with a porous structure formed from a large number of artificial voids, evenly distributed in the block, formed by foaming with a foaming agent or creating air with a gas-generating agent.

Aerated Lightweight Concrete

3. What is the structure of lightweight concrete?

- Lightweight concrete is made from lightweight coarse aggregates and sometimes some or all of the fine aggregate may be lightweight instead of regular aggregate. Structural lightweight concrete has a density (unit weight) in the order of 1440 to 1840 kg/m³. The normal weight of concrete is in the range of 2240 to 2400 kg/m³. For structural applications, the strength of the concrete must be greater than 2500 psi (17.0 MPa). The materials used in structural lightweight concrete are usually expanded shale, clay or slate materials. They are usually fired in a rotary kiln to develop a porous structure. Other products such as air-cooled blast furnace slag are also used.

The structure of lightweight concrete is often made of slate, clay, etc.

4. Characteristics and applications of lightweight concrete:

4.1. Lightweight concrete is good at resisting heat:

- In places with easy and convenient construction conditions, conventional construction methods can be used. In places with difficult and harsh construction conditions, construction methods using precast concrete panels can be used.

4.2. Fireproof lightweight concrete:

- Lightweight concrete has a very low thermal conductivity. That will help the space to be well insulated from the environment, creating a warm effect in winter and cool in summer. The structure of lightweight concrete does not change when exposed to sudden cold conditions and can withstand temperatures up to 1200 degrees Celsius.